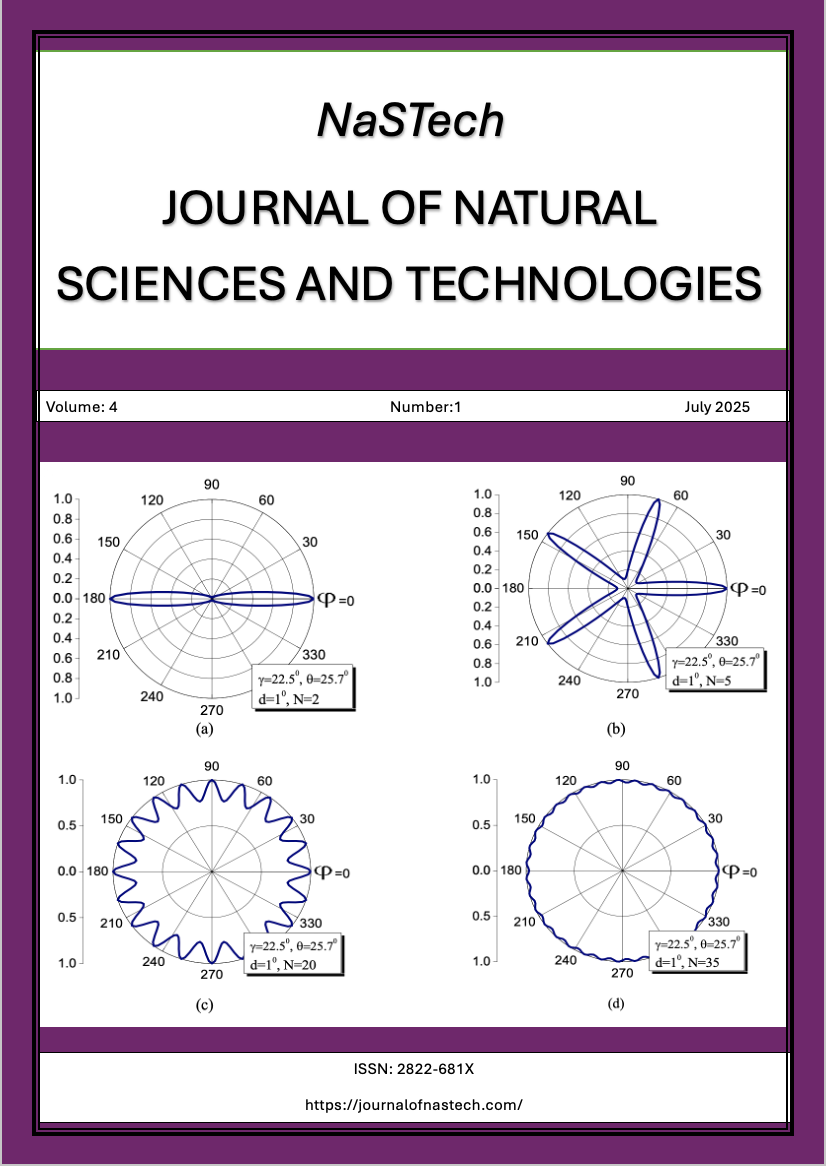

DEVELOPMENT OF A METHOD FOR PLANNING THE MOVEMENT OF A GRIPPING DEVICE FOR A 3-LINK COLLABORATIVE ROBOT MANIPULATOR

DOI:

https://doi.org/10.5281/zenodo.16617246Keywords:

Collaborative Robot, Trajectory Planning, Potential Field, Obstacle Avoidance, Gripping Device, Robot Manipulator, Artificial Forces, Modeling, Motion Dynamics, Safe Navigation, Mathematical Modeling, Artificial Potential Fields.Abstract

In the modern conditions of industrial automation development and the implementation of Industry 4.0 elements, the problem of safe and effective interaction of collaborative robot manipulators with the environment, including humans, other technical objects and possible obstacles, is of particular relevance. The task of planning the trajectory of the gripping device in conditions of limited workspace, the presence of obstacles and variable production conditions is especially critical, which requires the development of adaptive navigation methods. Given the need to ensure a high level of safety, accuracy and adaptability in the process of controlling robotic systems, the use of artificial intelligence methods and mathematical models capable of providing flexible response to changes in the spatial configuration of the environment is relevant. This article proposes a method for planning the movement and avoiding obstacles of the gripping device of a three-link collaborative robot manipulator based on the concept of artificial potential fields (APF).

The aim of the research is to create mathematical and algorithmic support for constructing the trajectory of a robotic gripping device, which allows for effective avoidance of collisions with obstacles, while ensuring accurate achievement of the target point in space. The subject of the research is the dynamic behavior of a three-link collaborative manipulator in a three-dimensional working environment taking into account the existing static obstacles. The method of artificial potential fields was used as the main research method, in which the attractive force to the target and the repulsive forces from obstacles are formed on the basis of potential functions. To ensure physical reliability and limit the velocity vector, methods of normalizing the velocity and limiting the space to specified limits were used. As part of the modeling, a system of equations of motion was constructed that takes into account the mass of the system, maximum speed and time step of integration.

The results of the numerical experiment demonstrated that the developed method provides smooth and safe passage of the trajectory without violating the boundaries of the working area, while the trajectory effectively bypasses obstacles in space and reaches the target point. Visualization of the trajectory in the form of a three-dimensional graph confirms the correctness of the algorithm, which can be applied in practical systems of industrial and service robots. The proposed approach can be the basis for further development of adaptive motion control systems in a changing environment and the use of sensor information fusion methods for processing moving or uncertain obstacles. Thus, the technique can be integrated into real robotic systems operating in cooperation with a person, while ensuring compliance with the principles of safety and efficiency

References

Arjomandi, M., Sanvelly, R. R., & Mukherjee, T. (2025). Variations in temperature, residual stress, and distortion in collaborative robot-assisted patterned additive manufacturing. Manufacturing Letters. https://doi.org/10.1016/j.mfglet.2025.01.001

Невлюдов, І. Ш., Євсєєв, В. В., & Гурін, Д. В. (2025). MODEL DEVELOPMENT OF DYNAMIC REPRESENTATION A MODEL DESCRIPTION PARAMETERS FOR THE ENVIRONMENT OF A COLLABORATIVE ROBOT MANIPULATOR WITHIN THE INDUSTRY 5.0 FRAMEWORK. Системи управління, навігації та зв’язку. Збірник наукових праць, 1(79), 42-48. https://doi.org/10.26906/SUNZ.2025.1.42-48

Kermenov, R., Foix, S., Borràs, J., Castorani, V., Longhi, S., & Bonci, A. (2025). Automating the hand layup process: On the removal of protective films with collaborative robots. Robotics and Computer-Integrated Manufacturing, 93, 102899. https://doi.org/10.1016/j.rcim.2024.102899

Carlier, R., Gillis, J., De Clercq, P., Borghesan, G., Stockman, K., & De Kooning, J. D. (2025). Performance Gain of Collaborative Versus Sequential Motion in Modular Robotic Manipulators for Pick-and-Place Operations. Machines, 13(5), 348. https://doi.org/10.3390/machines13050348

Attar, H., Abu-Jassar, A. T., Amer, A., Lyashenko, V., Yevsieiev, V., & Khosravi, M. R. (2022). Control system development and implementation of a CNC laser engraver for environmental use with remote imaging. Computational intelligence and neuroscience, 2022(1), 9140156, 2022. https://doi.org/10.1155/2022/9140156

Vladyslav Y. Comparative Analysis of the Basic Methods Used in Industry 4.0 and Industry 5.0. In Ricerche scientific and methods della loro realização: esperienza world and reality domestiche: Raccolta di articoli scientifici “ΛΌГOΣ” con gli atti of the IV Conference scientific and practical internazionale, Bologna. P. 114–116. https://doi.org/10.36074/logos-29.09.2023

Andrews, N. B., & Morgansen, K. A. (2025). Nonlinear Modeling and Observability of a Planar Multi-Link Robot with Link Thrusters. arXiv preprint arXiv:2503.14790. https://doi.org/10.48550/arXiv.2503.14790

Kusaka, T., & Tanaka, T. (2025). Partial Torque Tensor and Its Building Block Representation for Dynamics of Branching Structures Using Computational Graph. Robotics, 14(3), 31. https://doi.org/10.3390/robotics14030031

Gao, H., He, W., & Sun, C. (2025). Dynamic Modeling and Neural Network-Based Intelligent Control of Flexible Systems. John Wiley & Sons. ISBN 1394255284

Lochan, K., Seneviratne, L., & Hussain, I. (2025). Adaptive global super-twisting sliding mode control for trajectory tracking of two-link flexible manipulators. IEEE Access. https://doi.org/10.1109/ACCESS.2025.3557202

Nie, J. H., Li, D., Wang, H., Xiang, S. L., Yu, T., & Mao, J. X. (2025). Acoustic emission source location in complex structures based on artificial potential field-guided rapidly-exploring random tree* and genetic algorithm. Mechanical Systems and Signal Processing, 224, 112061. https://doi.org/10.1016/j.ymssp.2024.112061

Zou, W., & Li, J. (2025). Quantitative assessment approach of fuel cell operating state of safety based on potential field method. Renewable Energy, 238, 121782. https://doi.org/10.1016/j.renene.2024.121782

Zhang, C., Zhang, X., Yang, W., Zhang, G., Wan, J., Lei, M., & Dong, Z. (2025). Safe Path Planning Method Based on Collision Prediction for Robotic Roadheader in Narrow Tunnels. Mathematics, 13(3), 522. https://doi.org/10.3390/math13030522

Chala, O., Yevsieiev, V., Maksymova, S., & Abu-Jassar, A. (2025). MATHEMATICAL MODEL BASED ON MULTI-AGENT REINFORCEMENT LEARNING (MARL) AND PARTIALLY OBSERVABLE MARKOV DECISION PROCESS (POMDP) FOR MODELING CARGO MOVEMENT FOR A MOBILE ROBOTS GROUP. Multidisciplinary Journal of Science and Technology, 5(4), 480-489.

Yevsieiev, V., Hamdan, M., Maksymova, S., & Abu-Jassar, A. (2025). A HUMAN-CENTRIC APPROACH TO CONTROL COLLABORATIVE ROBOTS WITHIN INDUSTRY 5.0. Multidisciplinary Journal of Science and Technology, 5(5), 351-361.

Demska, N., Yevsieiev, V., Maksymova, S., & Alkhalaileh, A. (2025). Analysis of Methods, Models and Algorithms for a Collaborative Robots Group Decentralized Control. ACUMEN: International journal of multidisciplinary research, 2(2), 235-249.

Abu-Jassar, A. T., Attar, H., Amer, A., Lyashenko, V., Yevsieiev, V., & Solyman, A. (2025). Development and Investigation of Vision System for a Small-Sized Mobile Humanoid Robot in a Smart Environment. International Journal of Crowd Science, 9(1), 29-43. https://doi.org/10.26599/IJCS.2023.9100018

Nevliudov I. Sh. Mathematical Model of Block Process Planning in Systems of Allocation of Task Between Peopleand Collaborative Robots in the Framework of Industries 5.0 / I. Sh. Nevliudov, V. V. Yevsieiev, D. V. Gurin // Visnyk of Kherson National Technical University. – 2025. - Vol. 1, № 1(92). - P. 157-163. https://doi.org/10.35546/kntu2078-4481.2025.1.1.20

Yevsieiev, V., Abu-Jassar, A., & Maksymova, S. (2024). Calculation of the Distance to Objects in Collaborative Robots Workspace Using Computer Vision. Journal of universal science research, 2(11), 240-255.

Yevsieiev, V., Maksymova, S., Gurin, D., & Alkhalaileh, A. (2024). Data Fusion Research for Collaborative Robots-Manipulators within Industry 5.0. ACUMEN: International journal of multidisciplinary research, 1(4), 125-137.

Gurin, D., Yevsieiev, V., Maksymova, S., & Alkhalaileh, A. (2024). MobileNetv2 Neural Network Model for Human Recognition and Identification in the Working Area of a Collaborative Robot. Multidisciplinary Journal of Science and Technology, 4(8), 5-12.

Tian, Y., Yue, X., Wang, L., & Feng, Y. (2023). Vibration suppression of collaborative robot based on modified trajectory planning. Industrial Robot: the international journal of robotics research and application, 50(1), 45-55. https://doi.org/10.1108/IR-01-2022-0017

Zanchettin, A. M., Messeri, C., Cristantielli, D., & Rocco, P. (2022). Trajectory optimisation in collaborative robotics based on simulations and genetic algorithms. International Journal of Intelligent Robotics and Applications, 6(4), 707-723. https://doi.org/10.1007/s41315-022-00240-4

Proia, S., Cavone, G., Scarabaggio, P., Carli, R., & Dotoli, M. (2023). Safety Compliant, Ergonomic and Time-Optimal Trajectory Planning for Collaborative Robotics. IEEE Transactions on Automation Science and Engineering. https://doi.org/10.1109/TASE.2023.3331505

Pan, Y. J., Buchanan, S., Chen, Q., Wan, L., Chen, N., Forbrigger, S., & Smith, S. (2025). Survey on recent advances in planning and control for collaborative robotics. IEEJ Journal of Industry Applications, 14(2), 139-151. https://doi.org/10.1541/ieejjia.24005652

Wen, Y., & Pagilla, P. (2022). Path-constrained and collision-free optimal trajectory planning for robot manipulators. IEEE Transactions on Automation Science and Engineering, 20(2), 763-774. https://doi.org/10.1109/TASE.2022.3169989

Palmieri, G., & Scoccia, C. (2021). Motion planning and control of redundant manipulators for dynamical obstacle avoidance. Machines, 9(6), 121. https://doi.org/10.3390/machines9060121

Liu, J., Yap, H. J., & Khairuddin, A. S. M. (2024). Review on Motion Planning of Robotic Manipulator in Dynamic Environments. Journal of Sensors, 2024(1), 5969512. https://doi.org/10.1155/2024/5969512

Scalera, L., Giusti, A., & Vidoni, R. (2024). Trajectory Planning for Intelligent Robotic and Mechatronic Systems. Applied Sciences, 14(3), 1179. https://doi.org/10.3390/app14031179

Zhang, Z., Cao, Z., & Li, X. (2024). Neural dynamic fault-tolerant scheme for collaborative motion planning of dual-redundant robot manipulators. IEEE Transactions on Neural Networks and Learning Systems. https://doi.org/10.3390/app14031179

Szczepanski, R., Erwinski, K., Tejer, M., & Daab, D. (2024). Optimal Path Planning Algorithm with Built-In Velocity Profiling for Collaborative Robot. Sensors (Basel, Switzerland), 24(16), 5332. https://doi.org/10.3390/s24165332

Zhu, N., Xie, W. F., & Shen, H. (2024). Trajectory planning of cooperative robotic system for automated fiber placement in a leader-follower formation. The International Journal of Advanced Manufacturing Technology, 130(1), 575-588. https://doi.org/10.1007/s00170-023-12694-2

Lötstedt, P., & Mathias, S. (2025). Numerical integration of mechanical forces in center-based models for biological cell populations. Applied Mathematics and Computation, 486, 129069. https://doi.org/10.1016/j.amc.2024.129069

da Silva, J. S., de Assis, J. R., Fernandes, D. A., Rocha, N., & Sguarezi-Filho, A. J. (2025). Control performance analysis of an active power filter based on discrete predictors. Electric Power Systems Research, 243, 111470. https://doi.org/10.1016/j.epsr.2025.111470

Fouché, N., & Mentz-Coetzee, M. (2025). Automating monitoring and evaluation data analysis by using an open-source programming language. African Evaluation Journal, 13(1), 11. https://doi.org/10.4102/aej.v13i1.783

Out, F., Schanner, M., van Grinsven, L., Korte, M., & de Groot, L. V. (2025). Pymaginverse: A python package for global geomagnetic field modeling. Applied Computing and Geosciences, 100222. https://doi.org/10.1016/j.acags.2025.100222

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Journal of Natural Sciences and Technologies

This work is licensed under a Creative Commons Attribution 4.0 International License.